Wet Etching EquipmentThis equipment is used to remove the thin film which is not masked.

This is the equipment which cuts away the film with the chemicals.

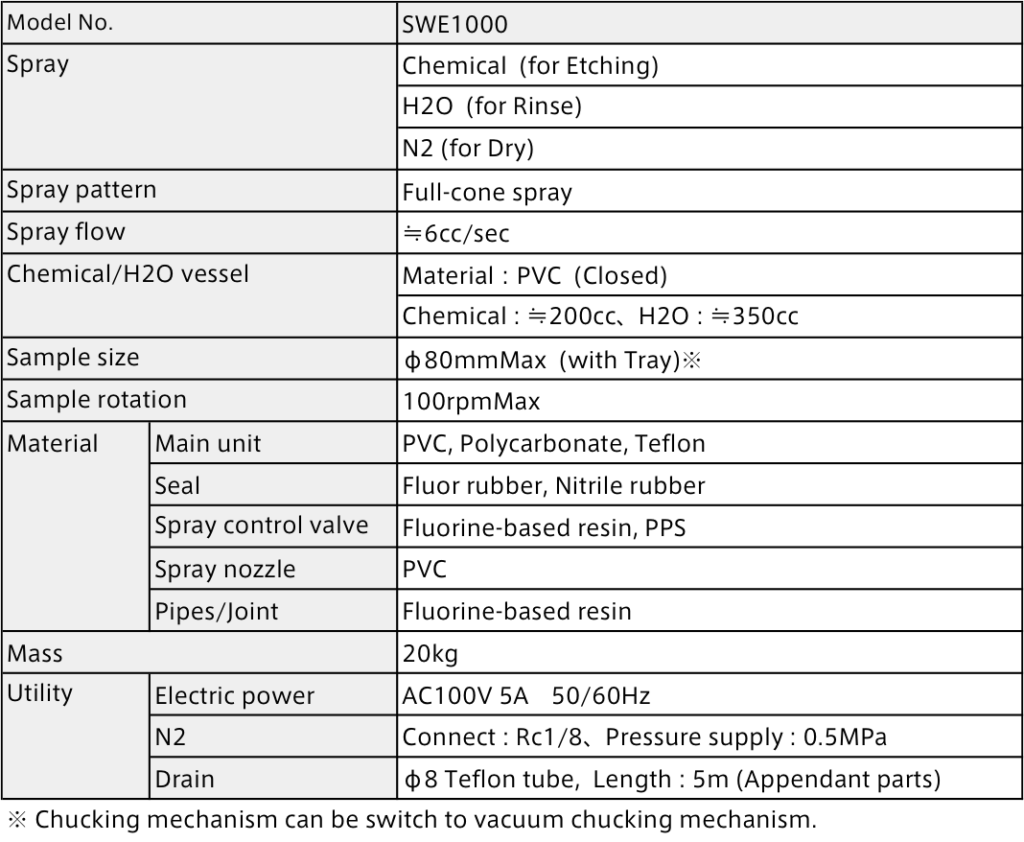

SWE1000

Chemical etching, H2O cleaning and N2 dry process are possible with the spray.

POINT

- The inside of container is configured by the high acid resistance resin.

- Easy etching for the oxide film and nitride film, etc.

- Spray time and order can be freely set.

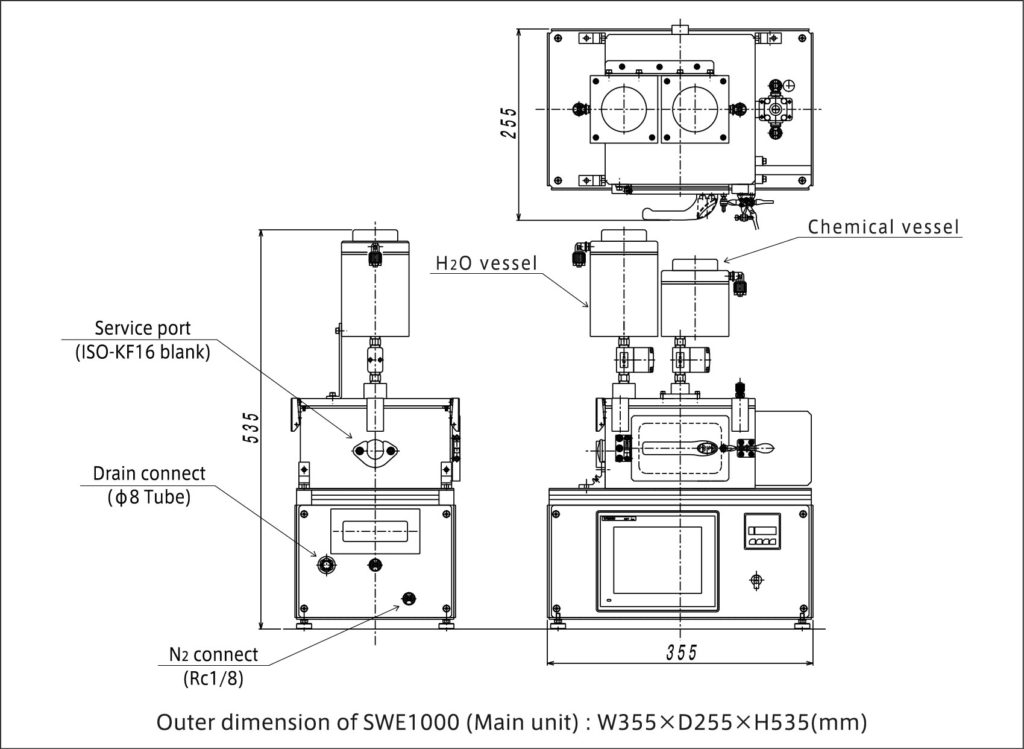

Outer dimension (Main unit)

W355mm×D255mm×H535mm

| Sample size | Sample rotation | Power | Mass |

|---|---|---|---|

| MAX Φ100mm | MAX 100rpm | AC100V | 20kg |

Outline・Application

Chemical etching can be done on the sample surface in a closed space.

For those who cannot afford to a dry etching system or have only to do a simple etching process, this model is the best solution.

This model focuses mainly on the oxide film (SiO2) and Nitride film (SiN).

・Chemical spray is done on the center of the sample from a part right above.

・Rinse water and N2 Injection nozzle angle can be adjusted.

・Spray distribution can be uniformed even with a small flow amount.

Feature

【Feature1】Parts inside a container

Parts inside a container is consisted of acid resistance resin・Elastomer.

A material against the acid which is difficult to handle is used.

【Feature 2】Spray Time

Each spray time for chemical etching, H2O cleaning and N2 dry can be set

per second on a touch screen.

【Feature 3】Automated Process

Each spray commands can be input up to 6 and are automatically processed in order of a setting. Recipe registration enables users to repeatedly perform the etching.

【Feature 4】Rotation Control

The rotation can be controlled up to 100rpm with a sample put on a dedicated tray. The chemical and H2O are sprayed evenly on the substrate surface by rotating the substrate.

【Feature 5】Touch Screen

Controls other than sample rotation number set time can be done on a touch screen.

SWE1000 Specification

SWE1000 Outer dimension